Description

Technical Parameters

Can be customized according to the drawings provided by customers for personalized customization.

Technical Reference Table

| Category | Specification / Range | Notes |

| Material | Aluminum Alloy 6061 / 7075/6063/6069 | Lightweight, high-strength, suitable for bicycles & e-bikes |

| Outer Diameter | 25–35 mm | Customizable per client drawings |

| Length | 250–400 mm | Adjustable based on requirements |

| Max Static Load | ≥1000 N | Ensures saddle stability under pressure |

| Surface Treatment | Anodizing / Polishing / Powder Coating | Anti-corrosion, oxidation-resistant |

| Weight | 300–450 g | Varies with length & wall thickness |

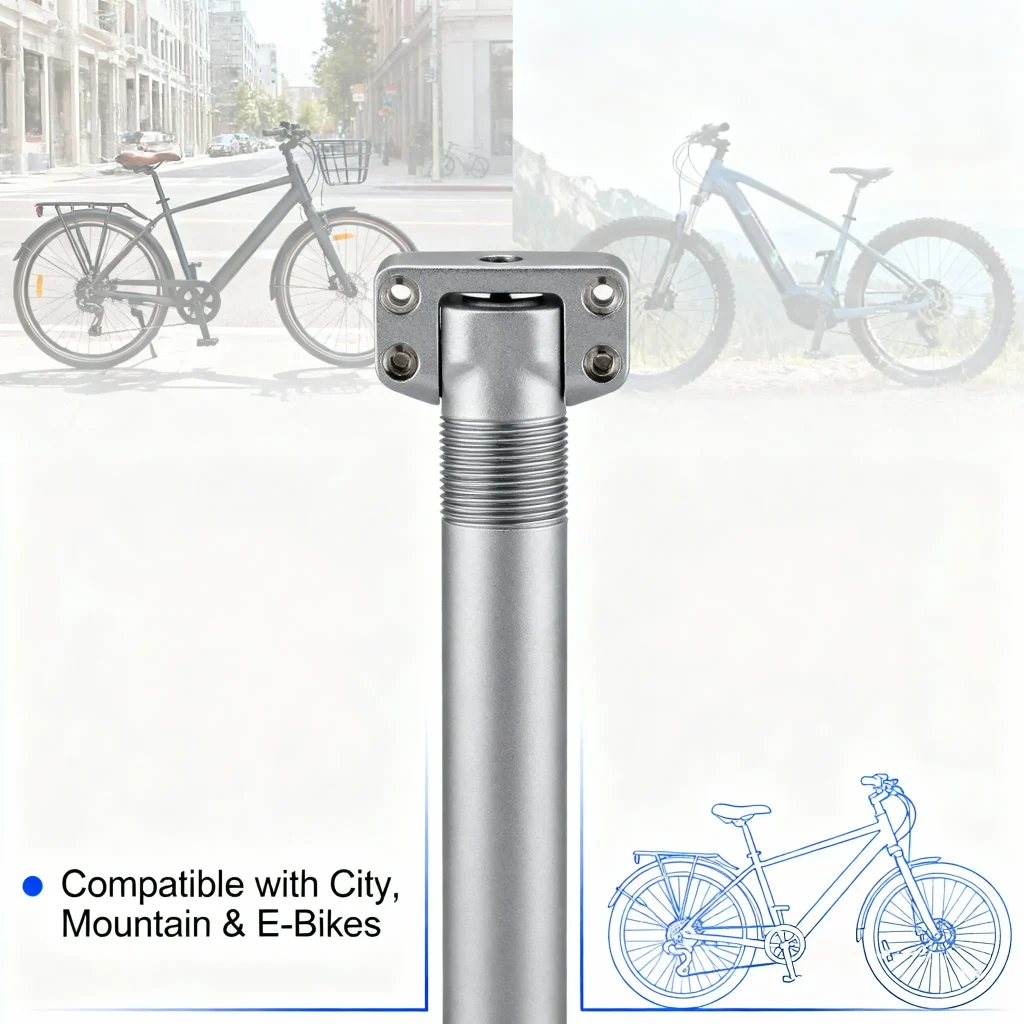

| Compatibility | Fits mainstream bicycles & e-bikes | Supports seat clamp diameters 28.6–31.8 mm |

| Customization | Fully per client drawings | OEM/ODM supported |

Technical Parameters

| Item | Specification / Options |

| Material | Aluminum Alloy 6061 / 7075 |

| Strength | High pressure resistance, deformation-resistant |

| Surface | Anodizing / Polishing / Powder Coating (anti-corrosion, oxidation-resistant) |

| Customization | By drawings, OEM/ODM supported |

| Compatibility | Fits mainstream bicycles & e-bikes; seat clamp diameters 28.6–31.8 mm |

Applications

- Suitable for all types of bicycles and e-bikes

- Ideal for saddle assembly, ensuring stable and comfortable riding experience

- Compatible with city commuter bikes, mountain bikes, and electric bicycles

- OEM parts for bicycle manufacturers, frame assemblers, and e-bike producers

Features

- High Precision CNC Machining → ±0.02mm tolerance, ensures smooth bearing rotation

- Multiple Surface Finishes → Anodized, Polished, or Painted to meet brand requirements

- Flexible Customization → Accepts drawings, prototype to mass production

Why Choose Us?

1. Deeply engaged in the bicycle and electric vehicle parts field for many years, with mature aluminum alloy bicycle and electric vehicle production technology, and stable and reliable product quality.

2. Can customize different specifications according to customer needs to meet the diversified shape requirements of vehicle frames.

3. Strict quality inspection process, from raw materials to finished products, with multiple controls to ensure product quality.