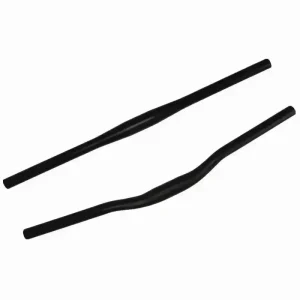

Description

Technical Parameters

Can be customized according to the drawings provided by customers for personalized customization.

Features

CNC precision machining, accurate size, strong installation adaptability.

Applications

For personalized detail processing, can accurately achieve customer drawing requirements, meeting strict size and shape requirements.

Why Choose Us?

Professional CNC machining equipment and technical team, with high – precision machining capabilities, meeting strict size and shape requirements.